InEpact Powerbox ORC

InEpact Powerbox ORC is a power unit that converts electricity from waste or geothermal heat according to the Organic Rankine Cycle principle (ORC).

The entire process is controlled and monitored by a PLC (Programmable Logic Controller), equipped with an operator panel. The PLC controls the process for optimal production of electricity.

It also monitors all components in the system.

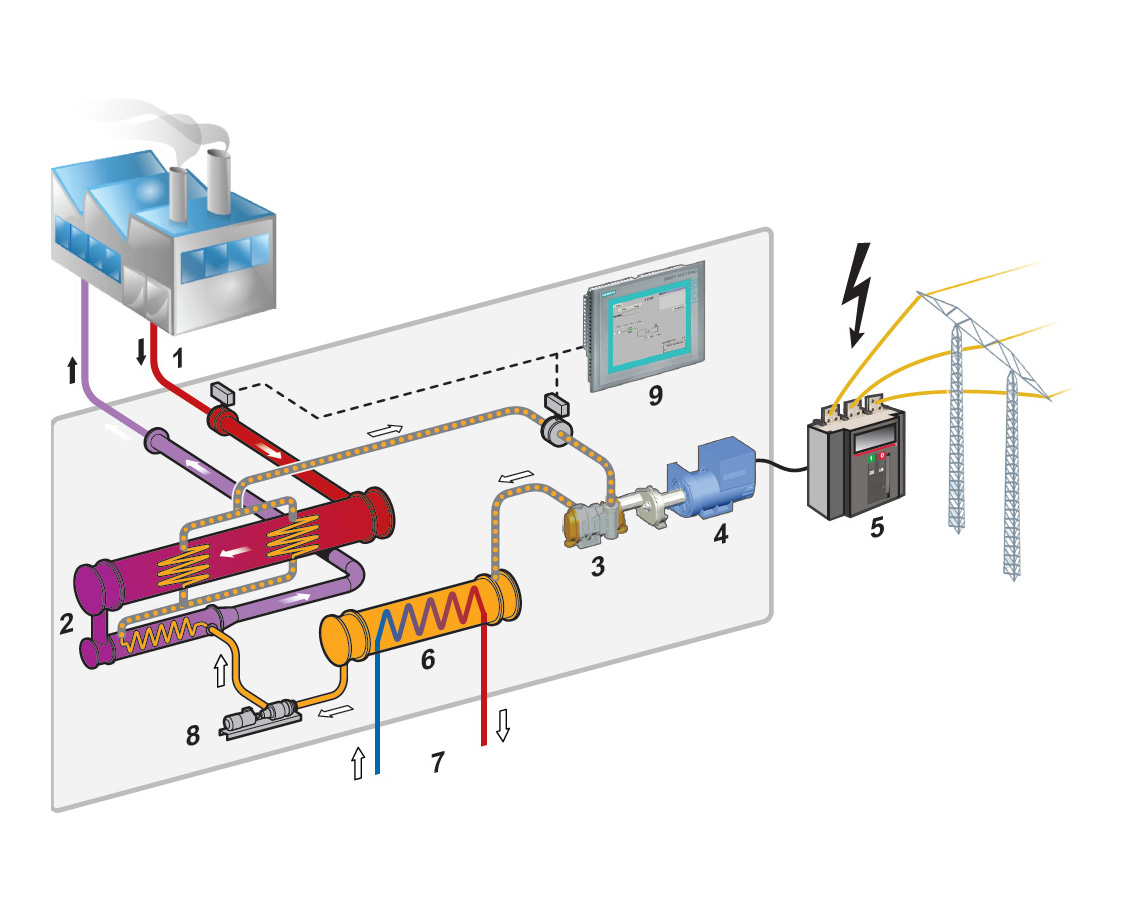

General process description of an ORC with a water-cooled condenser

[1-2] The working fluid is preheated and evaporated by a heat source.

[3-4] The pressurized gas expands through the turbine (expander) and the resulting shaft power is transformed into electricity in the generator

[5] Electricity is delivered to the grid through a circuit breaker located in the switchgear.

[8] The working fluid is condensed and re-circulated with a pump.

[9] An operator can manage and supervise the machine from the ORC operator panel.

Advantages with InEpact Powerbox ORC

- Available for variable working conditions

- Hot water/oil: temperature range 55 – 160 °C

- Steam: wet, saturated or dry steam ≤ 5 bar (a)

- Wide application range from 150 to 1600 kW

- Oil-free system

- InEpact’s latest profile, with high efficiency

- Safe and reliable grid connection

- Compact modular design

- Low maintenance cost, easy and simple operation

- Remote controlled, unattended operation

Working conditions InEpact Powerbox ORC

- Hot water/oil: temperature range 55 – 160°C

- Steam: wet, saturated or dry steam < 5 bar(a)

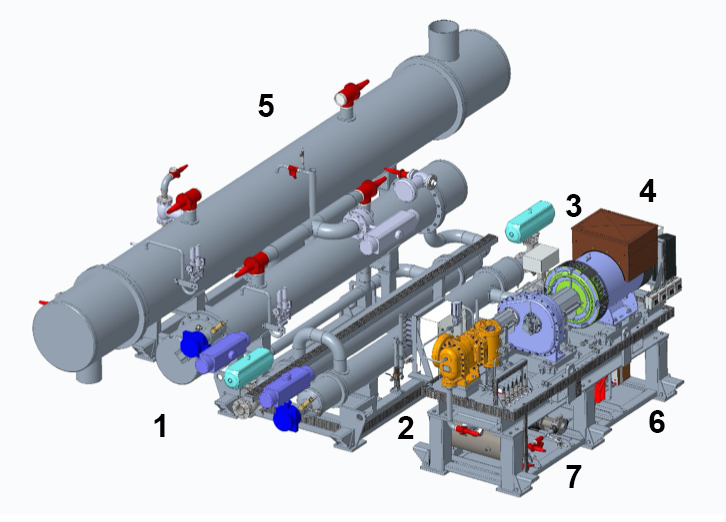

Main components

- Preheater and Evaporator

- Turbine (expander)

- Gearbox

- Generator

- Condenser

- Working fluid pump

- Lubrication system

The following components are not included in the image:

Cabinet with control and monitoring system (PLC with HMI)

Switchgear and frequency cabinets

WST

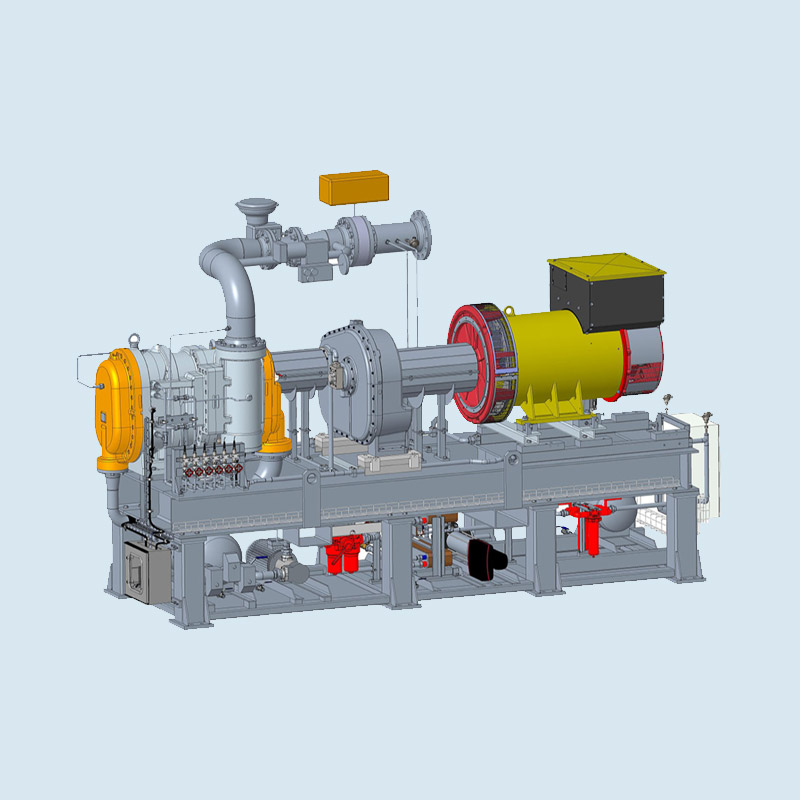

InEpact Powerbox WST

An InEpact Powerbox WST (Wet Steam Turbine) is a power unit that produces electricity from wet, saturated or dry steam.